Airborne/Structure-borne Ultrasound Testing

The word, "ultrasound," is used frequently in the medical field, but to us at UPI, it has a whole different meaning. Ultrasound is used with industrial applications and it is the ability to listen to sounds that are generated above 20,000 Hertz. Generally this range is much too high for our naked ears to hear, thus an external listening device is used to hear things like small amounts of air leaking from a connection or air compressor; a valve that doesn't close properly, allowing fluid or gas of some type to still pass through; the rubbing of metal together in an under lubricated bearing component on an electric motor; or other disturbances that create small amounts of friction and result in noise that can't be naturally heard by our ears. Below are three of the most commonly used applications for industrial use:

Air Leak Surveys, Steam Trap Audits, Bearing Lubrication.

Air Leak Surveys, Steam Trap Audits, Bearing Lubrication.

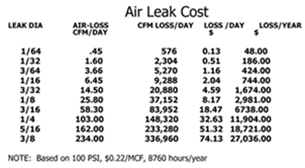

Air Leak SurveysThe US Department of Energy has performed extensive studies to determine the cost of operating air compressors and leaks based on size. Studies estimate that 40% of the energy used to generate compressed air goes to feed leaks in the air system. UPI can assist you in determining the locations of leaks within your facility. Contact us for a Free Air System Assessment.

|

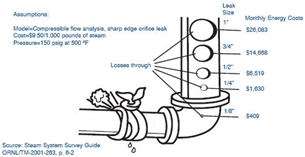

Steam Trap AuditsThe US Department of Energy has also performed extensive studies to determine the cost of operating steam systems and the energy wasted by trap blow by or complete failure. UPI can perform an audit of your steam traps to improve your system efficiency and improve your energy usage. Contact us for more information.

|

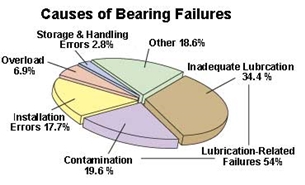

Bearing LubricationStudies by bearing manufacturers have found that over 50% of bearing failures occur due to improper lubrication practices. One of the best ways to counteract improper lubricating of bearings is by using structure-borne ultrasound to determine when and how much to lubricate your bearings. Contact UPI to assist you in starting an acoustical lubrication program.

|